This post is intended to outline the process of repairing damage to the diamond non-skid pattern that every Grady I have seen has on the gunwales and/or cockpit floor. Please note that I make no guarantees about the results you will achieve. I can only say this process worked very well for me.

Step 1: Prep the area.

After making all required glass repairs to the area, I sanded, faired, cleaned and masked off for application of the base coat of gelcoat. This was a large repair, so not all jobs will require as much prep work.

Step 2: Put down your base layer of gelcoat.

Thanks to much advice from Trident on www.classicmako.com, I figured out how to spray gelcoat with a Preval sprayer. The magic mix was 1 oz gelcoat, 6 ml acetone, a TINY dab of brown coloring agent and the appropriate amount of catalyst for the outside temperature. I mixed up larger batches, but using this ratio.

DO NOT add the catalyst until you have thoroughly mixed the other three components.

Step 3: Choose and prep a location to make your non-skid mold.

NOTE: Pre-made molds are available from Minicraft of FL (www.minicraft.com). I was in a time cruch so I chose to make my own instead of waiting a few days for delivery.

I chose a spot up on the bow because the pattern wasn't worn from people walking on it for the past 20 years. I cleaned the area, sprayed two layers of PVA down and masked it off for the next step.

Step 4: Make the mold.

I sprayed several coats of 3M spray-on bedliner over the area selected in Step 3. It was like $4 for a can at Autozone. I used up the whole can.

I let that cure overnight and pulled the pattern up in the morning.

Step 5: Trim and prepare the mold.

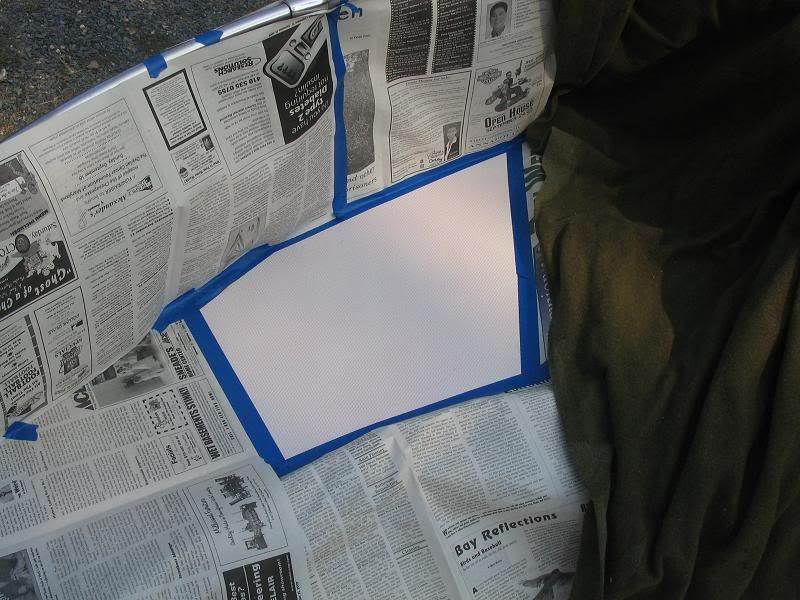

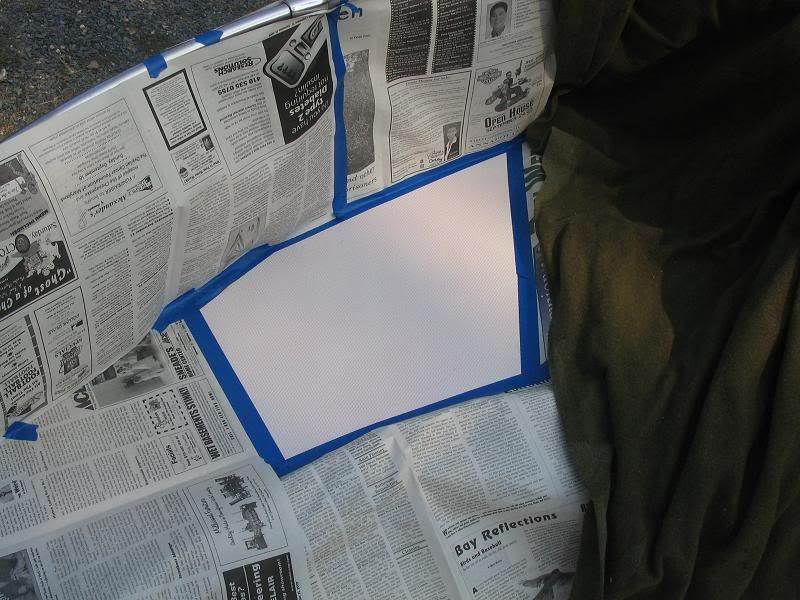

The next step in the mold making process was to trim the pattern to fit the area to be non-skidded. I masked off all areas that were not to received the non-skid and cut the pattern to fit inside these areas. Once I did this, I sprayed PVA on the patterned side of the mold and let it dry.

Step 6: Prep the base coat for non-skid. and apply the non-skid.

Once I sanded and cleaned the area to receive non-skid, I tried my best to lay down one end of the mold and get it to mesh with the existing non-skid. I taped that end down and folded the mold back over itself.

Reference the picture in Step 7.

Step 7: Apply the non-skid.

I applied the gelocat with a spreader and then folded the mold back on to the fresh gelcoat and layed some wax paper over everything. Then I rolled over the mold with a piece of AL pipe to squeege out any excess gelcoat.

The way paper was put down to serve the same purpose as spraying PVA over fresh gelcoat....to seal it off from the atmosphere and allow it to cure.

Step 8: Remove the pattern.

After allowing enough time for the non-skid to cure, I pulled up the wax paper and mold (it came up in pieces). I then had to do some light sanding around the edges to blend the surrounding areas.

Step 9: Touch up (may not be required, use your own judgement).

My last step was spraying a light layer of gelcoat around the edges of the new non-skid to build up the area slightly. I rushed this and didn't tint it quite enough, but I wasn't about to do it again.

LESSONS LEARNED:

1. Don't get the bedliner spray on any areas that didn't get mold release. It comes up, but not without a fight.

2. Give the molded bedliner at least 1 full day to cure before attempting to gelcoat. When I layed it down to cut it to size, it stuck to the existing gelcoat and I had to "help" it up with a plastic spreader. However, if you give it too much cure time and it gets brittle though. That has me thinking there's probably a better product out there for making the mold.

3. DO NOT RUSH! Take your time or you WILL screw it up.

Hope this help anyone looking to match similar patterns.

Step 1: Prep the area.

After making all required glass repairs to the area, I sanded, faired, cleaned and masked off for application of the base coat of gelcoat. This was a large repair, so not all jobs will require as much prep work.

Step 2: Put down your base layer of gelcoat.

Thanks to much advice from Trident on www.classicmako.com, I figured out how to spray gelcoat with a Preval sprayer. The magic mix was 1 oz gelcoat, 6 ml acetone, a TINY dab of brown coloring agent and the appropriate amount of catalyst for the outside temperature. I mixed up larger batches, but using this ratio.

DO NOT add the catalyst until you have thoroughly mixed the other three components.

Step 3: Choose and prep a location to make your non-skid mold.

NOTE: Pre-made molds are available from Minicraft of FL (www.minicraft.com). I was in a time cruch so I chose to make my own instead of waiting a few days for delivery.

I chose a spot up on the bow because the pattern wasn't worn from people walking on it for the past 20 years. I cleaned the area, sprayed two layers of PVA down and masked it off for the next step.

Step 4: Make the mold.

I sprayed several coats of 3M spray-on bedliner over the area selected in Step 3. It was like $4 for a can at Autozone. I used up the whole can.

I let that cure overnight and pulled the pattern up in the morning.

Step 5: Trim and prepare the mold.

The next step in the mold making process was to trim the pattern to fit the area to be non-skidded. I masked off all areas that were not to received the non-skid and cut the pattern to fit inside these areas. Once I did this, I sprayed PVA on the patterned side of the mold and let it dry.

Step 6: Prep the base coat for non-skid. and apply the non-skid.

Once I sanded and cleaned the area to receive non-skid, I tried my best to lay down one end of the mold and get it to mesh with the existing non-skid. I taped that end down and folded the mold back over itself.

Reference the picture in Step 7.

Step 7: Apply the non-skid.

I applied the gelocat with a spreader and then folded the mold back on to the fresh gelcoat and layed some wax paper over everything. Then I rolled over the mold with a piece of AL pipe to squeege out any excess gelcoat.

The way paper was put down to serve the same purpose as spraying PVA over fresh gelcoat....to seal it off from the atmosphere and allow it to cure.

Step 8: Remove the pattern.

After allowing enough time for the non-skid to cure, I pulled up the wax paper and mold (it came up in pieces). I then had to do some light sanding around the edges to blend the surrounding areas.

Step 9: Touch up (may not be required, use your own judgement).

My last step was spraying a light layer of gelcoat around the edges of the new non-skid to build up the area slightly. I rushed this and didn't tint it quite enough, but I wasn't about to do it again.

LESSONS LEARNED:

1. Don't get the bedliner spray on any areas that didn't get mold release. It comes up, but not without a fight.

2. Give the molded bedliner at least 1 full day to cure before attempting to gelcoat. When I layed it down to cut it to size, it stuck to the existing gelcoat and I had to "help" it up with a plastic spreader. However, if you give it too much cure time and it gets brittle though. That has me thinking there's probably a better product out there for making the mold.

3. DO NOT RUSH! Take your time or you WILL screw it up.

Hope this help anyone looking to match similar patterns.