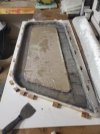

I figured I would share what I have been working on for the past year and a half. It is a 1997 209 Escape that was damaged pretty bad and had a rotted floor structure. Here are some before photos, but it has come quite a way so far.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1997 Escape 209

- Thread starter Rph1225

- Start date

Here are some of the construction photos along the way of the front end fixes.

Attachments

In the middle I decided to paint the boat a teal, as recommended by my wife and daughter. I had to get their buy in.

During this time, I had to recore the one hatch, but then mold a brand new one for the left side.

During this time, I had to recore the one hatch, but then mold a brand new one for the left side.

Attachments

During the past winter, when glassing days are hard to come by, I went about recoreing the center console. That led to making the console taller by about 8" so it is better for standing height, as I am changing from the tandem chairs to a leaning post.

I also got into some small projects, like molding a recessed battery switch for the rear of the boat.

I also got into some small projects, like molding a recessed battery switch for the rear of the boat.

Attachments

Over the spring I was able to draw up and create a t-top box for all my electronics. It is all out of Divinycell, so the box is about 35lbs fully loaded.

Attachments

Now to where I am close to today. I have the floor structure all ripped out up to good wood on the stringers, the new stringers back in and the decking going on.

Attachments

-

20230210_150536.jpg2.1 MB · Views: 45

20230210_150536.jpg2.1 MB · Views: 45 -

20230422_115205.jpg1,016.3 KB · Views: 46

20230422_115205.jpg1,016.3 KB · Views: 46 -

20230525_203245.jpg1.2 MB · Views: 44

20230525_203245.jpg1.2 MB · Views: 44 -

20230528_125448.jpg991.6 KB · Views: 43

20230528_125448.jpg991.6 KB · Views: 43 -

20240617_182152.jpg2.2 MB · Views: 45

20240617_182152.jpg2.2 MB · Views: 45 -

20240617_182134.jpg1.3 MB · Views: 46

20240617_182134.jpg1.3 MB · Views: 46 -

20240630_111045.jpg2.2 MB · Views: 44

20240630_111045.jpg2.2 MB · Views: 44 -

20240713_092533.jpg2.1 MB · Views: 45

20240713_092533.jpg2.1 MB · Views: 45

Here are a couple of new pics of the floor decking going in. I used 3/4" marine ply throughout, but used multiple layers of 1/4" marine ply with 1708 between the layers to blend the 3/4" decking to the existing 1/2" decking. I also had a bid of time to quickly do a mold for the corner of the pan that the center console base sits into.

Attachments

Here are some new pics of the fuel tank set in place, decking installed and seamed and the first coat of glass down. In the process I molded a new hatch recess in the floor which sits directly under the leaning post. The hope is to use some of the space that Grady covered up on the original design. Also installed is a molded battery switch/voltage gauge recess panel. Fairing of the decking and painting comes next.

Attachments

Over the past few days, I finally got to a milestone. All the glasswork on the inside of the hull has been done and now on to fairing, primer and paint. It still looks rough, but all the itching should be subsiding soon.

Attachments

Sdfish

GreatGrady Captain

- Joined

- Sep 15, 2013

- Messages

- 522

- Reaction score

- 180

- Points

- 43

- Location

- San Diego, California

- Model

- Adventure

Finally it is moving into a finish stage. I was able to get all the filler on the floor and moving into primer. Here is a pic of a tool I had to make the sand the interior radiuses. It uses a oscillating tool and 1-1/2" PVC. It worked great and sanded fast.

Attachments

Getting in the last few days of good weather here in MD, I was able to get some painting done. Also, finally after about 2 years, the console and t-top went back on. Hopefully, I can get the remaining painting complete, so wiring and plumbing can begin.

Attachments

PointedRose

Well-Known Member

- Joined

- Feb 11, 2021

- Messages

- 704

- Reaction score

- 215

- Points

- 43

- Location

- San Francisco

- Model

- Overnighter

![20241030_173009[1].jpg](/data/attachments/32/32364-601d15ad7427977817848f3b02030922.jpg?hash=YB0VrXQnl3)

![20241103_144406[1].jpg](/data/attachments/32/32366-0da913481fde4cfca4ee074efbe66adc.jpg?hash=DakTSB_eTP)

![20241103_144358[1].jpg](/data/attachments/32/32365-7cef6e16840c18756b11d36a6c5a7418.jpg?hash=fO9uFoQMGH)