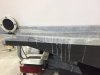

I'm doing a restoration on a 1994 Grady 209, fortunately for me, the previous owner didn't install trim tabs, he only did a crappy job installing a fish finder transducer, when it was removed from the transom, it had some moisture which I fixed. So I wanted to install a set of trim tabs, but I absolutely hate the idea of any screws or holes below the waterline......I don't care how much 5200 you use, over time the water will migrate into the laminate. The decision was made to install fiberglass mounting pads to the hull wherever a fastener was required. I used 1/2' solid fiberglass pads, machined them to size, pre-drilled and tapped holes and then fused them to the hull with Plexus structural adhesive. I've been using Plexus for years and it is insanely strong above and below the waterline and the fiberglass always fails, never the bond line. So my Grady will now have proper mounting pads for the trim tabs, transducer and transducer wire clip, there are no holes in my hull and I will never have water leaks. Attached are some pics, after work on Monday, I will clean up around the glue line and paint bottom paint over the pads. The fittings will be installed on their respective pads with machine screws and a bit of 5200.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A new way to install trim tabs

- Thread starter Jcontour

- Start date

Fishtales

Well-Known Member

- Joined

- Jan 31, 2005

- Messages

- 8,029

- Reaction score

- 1,286

- Points

- 113

nice. do you have to get all the gelcoat off or can you just sand it down a bit before applying the Plexus?

I saw in a thread that the Onslow Bay boat builders use Plexus as their adhesive for deck to hull joints as well as the transom area versus fairing compound that others use. Looks to be a very solid way to do it.... Would like to see more pics when completed.

tx

I saw in a thread that the Onslow Bay boat builders use Plexus as their adhesive for deck to hull joints as well as the transom area versus fairing compound that others use. Looks to be a very solid way to do it.... Would like to see more pics when completed.

tx

gw204

Well-Known Member

Good idea.

It also seems like much more work than just over drilling the holes, filling with thickened epoxy and the redrilling.

It also seems like much more work than just over drilling the holes, filling with thickened epoxy and the redrilling.

Ya, certainly more work than drilling and back filling with thickened epoxy. My take is that if there are fasteners that go into the wood transom, water will someday migrate through, even if a proper job is done with epoxy, someday you'll hit a big wave and something will have a micro crack and water will get in. With this method, you are guaranteed no through transom penetrations. With regards to Plexus and a proper bond, personally I ground the gel back a bit but didn't go through to the glass, cleaned with acetone and glued. I suppose that an argument could be made for grinding the gel right off, but I think it's just fine to bond to a thin gelcoat and will NEVER shear off as thinned out gel is very close to the glass laminate and homogenous with the skin coat resin/glass. Plexus is used all over these days, stringers, hull/deck, bulkheads....the nice think about it is that it has 150% elongation before it fails, it's far less brittle than a traditional polyester/vinyl ester bonding compound, and does not crack under extreme dynamic loading.

twoboater

Member

I like how you did this. after looking at the pics I had an idea to counter-sink bolts in the fiberglass pads from the back side and use them as mounting studs for your tabs instead of self-tapping screws. Nice work.

That's a great idea, if there ever is a next time, I'll counter bore the back side and bond some nuts. The current iteration has tapped holes in which I'll use machine screws rather than self tapping, but nonetheless, bonded nuts would be good.

billybaru13

New Member

- Joined

- Jun 12, 2018

- Messages

- 1

- Reaction score

- 0

- Points

- 1

I'm doing a restoration on a 1994 Grady 209, fortunately for me, the previous owner didn't install trim tabs, he only did a crappy job installing a fish finder transducer, when it was removed from the transom, it had some moisture which I fixed. So I wanted to install a set of trim tabs, but I absolutely hate the idea of any screws or holes below the waterline......I don't care how much 5200 you use, over time the water will migrate into the laminate. The decision was made to install fiberglass mounting pads to the hull wherever a fastener was required. I used 1/2' solid fiberglass pads, machined them to size, pre-drilled and tapped holes and then fused them to the hull with Plexus structural adhesive. I've been using Plexus for years and it is insanely strong above and below the waterline and the fiberglass always fails, never the bond line. So my Grady will now have proper mounting pads for the trim tabs, transducer and transducer wire clip, there are no holes in my hull and I will never have water leaks. Attached are some pics, after work on Monday, I will clean up around the glue line and paint bottom paint over the pads. The fittings will be installed on their respective pads with machine screws and a bit of 5200.

I am about to do the same thing to my 209, and had a quick question. Did you pad out where the top of the actuator lands on the transom as well?