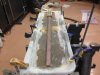

Well, I removed the rear floor section to change a pump. I discovered a waterlogged floor section So, since it had to fixed, I might as well do it right. I removed the soaked wood. replaced it with foam and fiberglass. I added a stringer for additional support. I removed the main floor to tiger hair the hinge end. I did not want to insert new screws into an area that I could not see. So I removed it to be safe. I beefed up the area under the hinge area with marine plywood along the hinge area. Flush hinges were inset. the round hatch was filled, and rubber gasket was installed to stop some of the water. the area works great for dirty storage. Dale, 2002 265 express.

So, since it had to fixed, I might as well do it right. I removed the soaked wood. replaced it with foam and fiberglass. I added a stringer for additional support. I removed the main floor to tiger hair the hinge end. I did not want to insert new screws into an area that I could not see. So I removed it to be safe. I beefed up the area under the hinge area with marine plywood along the hinge area. Flush hinges were inset. the round hatch was filled, and rubber gasket was installed to stop some of the water. the area works great for dirty storage. Dale, 2002 265 express.

Attachments

-

IMG_5755 (640x480).jpg115.6 KB · Views: 3,416

IMG_5755 (640x480).jpg115.6 KB · Views: 3,416 -

IMG_5754 (640x480).jpg136.9 KB · Views: 3,416

IMG_5754 (640x480).jpg136.9 KB · Views: 3,416 -

IMG_5470 (640x480).jpg164.2 KB · Views: 3,416

IMG_5470 (640x480).jpg164.2 KB · Views: 3,416 -

IMG_5452 (640x480).jpg153 KB · Views: 3,416

IMG_5452 (640x480).jpg153 KB · Views: 3,416 -

IMG_5449 (640x480).jpg188.1 KB · Views: 3,416

IMG_5449 (640x480).jpg188.1 KB · Views: 3,416 -

IMG_5446 (640x480).jpg162.7 KB · Views: 3,416

IMG_5446 (640x480).jpg162.7 KB · Views: 3,416 -

IMG_5441 (640x480).jpg165.5 KB · Views: 3,416

IMG_5441 (640x480).jpg165.5 KB · Views: 3,416 -

hatch1.jpg140.4 KB · Views: 3,407

hatch1.jpg140.4 KB · Views: 3,407