- Joined

- Jan 31, 2005

- Messages

- 8,334

- Reaction score

- 1,373

- Points

- 113

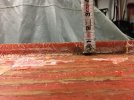

I noticed a little brown water dripping from my small cockpit deck piece that resides under the rear seat (when seat folded down) when putting the boat away for the season. The deck piece has an access port as well as a vertical door that swings down to allow access to the aft bilge area. It is about 4' by 18" or so in size. I knew what it was - water intrusion and made a mental note to pull the deck and investigate the coring. On the back side of the deck cover, there is a single layer of glass that is put down over the core (XL Greenwood plywood) but the core is in pieces with some V notches to put them together like a puzzle. Not sure why this is done maybe someone can chime in. When I got the piece home today, I could see some mold under the layer of glass and what looked to be some minor delamination maybe due to the cold winter and the wood core being wet.

The good.

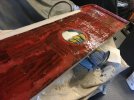

- I could remove most of the single layer of glass with a hammer and a pry bar. Near the rounded edges, it popped out around the top side structure. I've got to clean up an edge but other than that, it came out pretty clean.

- The top side is undamaged. I can install a new core and glass it in to make it solid again.

- The XL Greenwood was wet thru and didn't show any signs of rot. It was dark brown from the water and mold but really not bad structurally for wood. Most pieces popped out with the bar and hammer.

- The repair should be fairly straight forward and easy to execute.

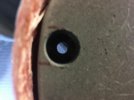

- The deck plate does not screw into the core. The screws go into fiberglass on the deck cover.

The bad

- Cover easily weighed 2X dry weight. If the color of the glass and core didn't scream wet, the weight did.

- The screws that attach the piece to the deck go through the core in places. This was likely one source of water entry. Water gets behind the screw head, gravity takes over and it gets into some of the pieces of wood. Unsure if it migrates to other pieces, my guess is yes. Once in there and if it goes through a few freeze/thaw or maybe just migration it gets into all the pieces. While pieces they are tightly fitted so water could easily move to adjacent core pieces.

- The screws that hold the deck plate frame to the glass are simply screwed through the fiberglass. No backing material. The frame is caulked, but I'm sure water can get into these screws. This water should not get in the core.

- The screws that hold the deck cover to the cockpit floor are the same. They screw into fiberglass on the cockpit floor only. Pretty crappy design. There are small pieces of rubber that sit between the deck cover and the cockpit floor to mitigate noise and the edge is caulked to keep water out. This caulk also helps to hold the cockpit cover in place.

- The wood core came out pretty easy and was solidly attached to the top in about 15% of the coring surface area.

The scary.

- After seeing this, I'm wondering what else is lurking. I hear the stories of scuppers being under water and boats being slower than previous years and wonder if this is a symptom of a bigger wet boat problem. If the core gets wet, she'll be real heavy.

All in all, not a difficult fix. I will recore and ensure deck screw holes are cut around. I'll secure the deckplate frame with stainless bolts with backside washers and nyloc nuts to better secure the plate to the deck.

I'm guessing a gallon of the west system, some marine plywood or potentially new coring material and a layer or two of glass will do the job. I'll post some pics later.

The good.

- I could remove most of the single layer of glass with a hammer and a pry bar. Near the rounded edges, it popped out around the top side structure. I've got to clean up an edge but other than that, it came out pretty clean.

- The top side is undamaged. I can install a new core and glass it in to make it solid again.

- The XL Greenwood was wet thru and didn't show any signs of rot. It was dark brown from the water and mold but really not bad structurally for wood. Most pieces popped out with the bar and hammer.

- The repair should be fairly straight forward and easy to execute.

- The deck plate does not screw into the core. The screws go into fiberglass on the deck cover.

The bad

- Cover easily weighed 2X dry weight. If the color of the glass and core didn't scream wet, the weight did.

- The screws that attach the piece to the deck go through the core in places. This was likely one source of water entry. Water gets behind the screw head, gravity takes over and it gets into some of the pieces of wood. Unsure if it migrates to other pieces, my guess is yes. Once in there and if it goes through a few freeze/thaw or maybe just migration it gets into all the pieces. While pieces they are tightly fitted so water could easily move to adjacent core pieces.

- The screws that hold the deck plate frame to the glass are simply screwed through the fiberglass. No backing material. The frame is caulked, but I'm sure water can get into these screws. This water should not get in the core.

- The screws that hold the deck cover to the cockpit floor are the same. They screw into fiberglass on the cockpit floor only. Pretty crappy design. There are small pieces of rubber that sit between the deck cover and the cockpit floor to mitigate noise and the edge is caulked to keep water out. This caulk also helps to hold the cockpit cover in place.

- The wood core came out pretty easy and was solidly attached to the top in about 15% of the coring surface area.

The scary.

- After seeing this, I'm wondering what else is lurking. I hear the stories of scuppers being under water and boats being slower than previous years and wonder if this is a symptom of a bigger wet boat problem. If the core gets wet, she'll be real heavy.

All in all, not a difficult fix. I will recore and ensure deck screw holes are cut around. I'll secure the deckplate frame with stainless bolts with backside washers and nyloc nuts to better secure the plate to the deck.

I'm guessing a gallon of the west system, some marine plywood or potentially new coring material and a layer or two of glass will do the job. I'll post some pics later.