You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Marlin Rear Hatch Mod?

- Thread starter Meanwhile

- Start date

DennisG01

GreatGrady Captain

- Joined

- Sep 1, 2013

- Messages

- 7,428

- Reaction score

- 1,412

- Points

- 113

- Location

- Allentown, PA & Friendship, ME

- Model

- Offshore

(Boat model doesn't matter here)

That's a good idea.

You may want to just install a nice, waterproof access plate above your fuel sending unit. That will give you easy access to the pull the sending unit to make pumping out the water quick and easy.

That's a good idea.

You may want to just install a nice, waterproof access plate above your fuel sending unit. That will give you easy access to the pull the sending unit to make pumping out the water quick and easy.

SkunkBoat

GreatGrady Captain

- Joined

- Oct 12, 2017

- Messages

- 4,717

- Reaction score

- 1,663

- Points

- 113

- Location

- Manasquan Inlet NJ

- Website

- www.youtube.com

- Model

- Express 265

g0tagrip

GreatGrady Captain

I have the same boat, 2007 Marlin, I put a floor hatch over the aft for access to the fuel water separators. I can send you pictures if you email me your address as I have yet to break the code on posting pictures here.

My email address is: g0tagrip33@gmail.com

Note the 0 is a zero not an ooo

My email address is: g0tagrip33@gmail.com

Note the 0 is a zero not an ooo

I think I saw your post on FB, a really nice aluminum hatch?I have the same boat, 2007 Marlin, I put a floor hatch over the aft for access to the fuel water separators. I can send you pictures if you email me your address as I have yet to break the code on posting pictures here.

My email address is: g0tagrip33@gmail.com

Note the 0 is a zero not an ooo

How waterproof has that hatch been? I don't want bloody tuna water getting to the bilge.

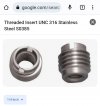

So I had some brass inserts to try and I practiced on 2 of them. I had a short bolt and used 2 nuts to insert them with some shop white wood glue. I left them just a bit proud. I noticed it was difficult to start them straight, a longer bolt might help. I'm too cheap to buy their install tool.

So I'll test the strength and rotational force they would take. I'll post back tomorrow.

As I don't know much about wood working I thought I'd better practice.

So I'll test the strength and rotational force they would take. I'll post back tomorrow.

As I don't know much about wood working I thought I'd better practice.

DennisG01

GreatGrady Captain

- Joined

- Sep 1, 2013

- Messages

- 7,428

- Reaction score

- 1,412

- Points

- 113

- Location

- Allentown, PA & Friendship, ME

- Model

- Offshore

If it was me, I'd probably put them in with epoxy. If you're going into solid wood, there is zero chance that they'd pull out.

I think the only tricky part is making sure you get them centered with the existing holes in the panel. But ti shouldn't be too bad if you follow the existing screw hole in the deck... as long as it's pretty straight.

I think the only tricky part is making sure you get them centered with the existing holes in the panel. But ti shouldn't be too bad if you follow the existing screw hole in the deck... as long as it's pretty straight.

SkunkBoat

GreatGrady Captain

- Joined

- Oct 12, 2017

- Messages

- 4,717

- Reaction score

- 1,663

- Points

- 113

- Location

- Manasquan Inlet NJ

- Website

- www.youtube.com

- Model

- Express 265

The hatch has wood core. The flange in the deck is just glass...right? Where is the threaded insert going?

Maybe I'm having a senior moment...

I glued a strip of 3/4" pvc board under the deck flange. Screw goes thru hatch then old hole in flange then tightens up on the pvc board.

Maybe I'm having a senior moment...

I glued a strip of 3/4" pvc board under the deck flange. Screw goes thru hatch then old hole in flange then tightens up on the pvc board.

A portion of the lip is into 3/4 ply, but the edges are into a 1/4" glass. Good issue spotting. I think the glass could be served by a crimp insert. I have a kit to do that but would need to source stainless inserts.The hatch has wood core. The flange in the deck is just glass...right? Where is the threaded insert going?

Maybe I'm having a senior moment...

I glued a strip of 3/4" pvc board under the deck flange. Screw goes thru hatch then old hole in flange then tightens up on the pvc board.

I'll use the old screws and life caulk until the season is over. Then play with an update. I could epoxy some ply under the glass to use the inserts I'm testing. I have to do that in one corner anyway and their screw placement is on the very edge of the glass on one corner.

Here are your photos.I have the same boat, 2007 Marlin, I put a floor hatch over the aft for access to the fuel water separators. I can send you pictures if you email me your address as I have yet to break the code on posting pictures here.

My email address is: g0tagrip33@gmail.com

Note the 0 is a zero not an ooo

Legend

GreatGrady Captain

- Joined

- Jun 29, 2006

- Messages

- 1,477

- Reaction score

- 205

- Points

- 63

- Location

- Southern New England

- Model

- Sailfish

I used these brass inserts around windows to secure fiberglass hurricane coverings during noreasters. They are very secure. I found the easiest way to get them in straight is to use a bolt, nut and a rachet. The nut gets put on the bolt and then just use a rachet to spin the insert in. if you don't use the nut on the bolt, the bolt will get screwed into the the insert so tight that when you got to remove if the insert will come out too.

g0tagrip

GreatGrady Captain

glacierbaze

Well-Known Member

- Joined

- Jul 6, 2012

- Messages

- 2,544

- Reaction score

- 662

- Points

- 113

- Age

- 76

- Model

- Seafarer

SkunkBoat

GreatGrady Captain

- Joined

- Oct 12, 2017

- Messages

- 4,717

- Reaction score

- 1,663

- Points

- 113

- Location

- Manasquan Inlet NJ

- Website

- www.youtube.com

- Model

- Express 265

yep, even a 1/4-20 oval phillips is going to require a bigger countersink...which opens up the glass to the wood and probably goes over the edge of the deck lid.If you use a 1/4 by 20 insert, what kind of bolt heads are you going to have above deck, that are not a trip, or stub your toes hazard?

and they will all have to line up perfectly all the way around.

Fishtales

Well-Known Member

- Joined

- Jan 31, 2005

- Messages

- 8,232

- Reaction score

- 1,344

- Points

- 113

Not a lot of material on the flange for those inserts. Maybe epoxy them in, but I'd be afraid that there would be issues down the road.

I like the hatch idea, great when seat down. It appears to sit a little proud and it may be a bit of PIA when seat is up. No easy solution. You could fill the screw holes and just seal. I'm guessing the screws do very little anyway.

I like the hatch idea, great when seat down. It appears to sit a little proud and it may be a bit of PIA when seat is up. No easy solution. You could fill the screw holes and just seal. I'm guessing the screws do very little anyway.

jip40

GreatGrady Captain

- Joined

- Mar 13, 2013

- Messages

- 218

- Reaction score

- 19

- Points

- 18

- Location

- Atlanta / Carrabelle, FL

- Model

- Express 330

Following as I have similar issue with my 330 - except that the flange has been cracked & pretty much f**cked up during a recent repower. I am going to have to have to have a service tech cleanup the flange area before proceeding

jip40

GreatGrady Captain

- Joined

- Mar 13, 2013

- Messages

- 218

- Reaction score

- 19

- Points

- 18

- Location

- Atlanta / Carrabelle, FL

- Model

- Express 330

g0ta - do you have the mfg and size or model of the hatch you used - thanks JeffI have the same boat, 2007 Marlin, I put a floor hatch over the aft for access to the fuel water separators. I can send you pictures if you email me your address as I have yet to break the code on posting pictures here.

My email address is: g0tagrip33@gmail.com

Note the 0 is a zero not an ooo

SkunkBoat

GreatGrady Captain

- Joined

- Oct 12, 2017

- Messages

- 4,717

- Reaction score

- 1,663

- Points

- 113

- Location

- Manasquan Inlet NJ

- Website

- www.youtube.com

- Model

- Express 265