I've done that before. How else would you do that really? Thats what its for. it was $99 at HF!

Think of using it to set my current motors off to the side without disconnecting. I THINK it can be done. I need to do a little work on the lower bolt holes.

FYI. I repowered my 265 a few years ago. Work done by dealer. I didn't have any transom work done. The cap is well sealed, though certainly not shiny and new.

They just bolted new motors on. If I had time,and weather, and was doing it myself, I would have glassed over the transom seam.

But my main point is the lower holes. The inside glass is never flat and smooth. The washers tend to cut into the glass over time. Replacing bolts and tightening will eventually make it worse.

I suggest putting a wider glass "eyepatch" over each inside lower hole. I am assuming that I can work through the motorwell pieholes.

Since you have your motors off, Please tell me if I am wrong!

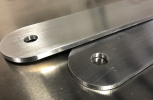

Also, use lower transom plates. I've been looking at some that are not cast aluminum, they are rolled plate.

I had the typical cast transom plate on my old boat and it eventually cracked.