You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Removing Thru Hulls for resealing

- Thread starter TLCObsession

- Start date

Fixit

Well-Known Member

- Joined

- Jun 26, 2022

- Messages

- 123

- Reaction score

- 37

- Points

- 28

- Age

- 44

- Model

- Islander

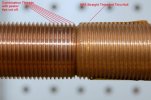

the thread pitch and diameter are identical, but NPS lacks the 1.8 degree taper, so a big tap will make that change easily. Yes it does remove a tiny bit of material but doubling the thread engagement would make the connection stronger, plus now you have threads that self seal instead of relying on pipe dope, thread tape (or Grady white's silicone)You could have used a flanged adapter by Groco. It's straight thread on the inside (bottom) and NPT on the outside (top). Plus, because of the flange, it's a much more secure way to install seacocks/etc. The ideal way, and I don't know why Grady doesn't do this, is to first glass a block onto the hull, then screw down the flange adpater onto the thru-hull and then screw the flange to the block. Everything is MUCH more secure that way. Plenty of other manufacturers do this.

I, honestly, didn't even know you could change straight threads to NPT. Does that compromise anything by making the pipe/thread thinner?

Attachments

DennisG01

GreatGrady Captain

- Joined

- Sep 1, 2013

- Messages

- 7,816

- Reaction score

- 1,542

- Points

- 113

- Location

- Allentown, PA & Friendship, ME

- Model

- Offshore

Interesting. I never really thought to do that, before. I guess it doesn't take off as much material as I would have thought. Definitley - better thread engagement is important.the thread pitch and diameter are identical, but NPS lacks the 1.8 degree taper, so a big tap will make that change easily. Yes it does remove a tiny bit of material but doubling the thread engagement would make the connection stronger, plus now you have threads that self seal instead of relying on pipe dope, thread tape (or Grady white's silicone)

Scottywotty

Member

- Joined

- Nov 2, 2023

- Messages

- 12

- Reaction score

- 0

- Points

- 1

- Age

- 66

- Model

- Adventure

I would like to resurrect this thread,

we replaced all of the thruhulls w/ stainless, however getting to all of the clamps, elbows, and hoses to get good tight connections is impossible. I was just wondering what anyone else may have done that we haven't thought of? This is a real issue for a boat that is in a slip, ultimately we just installed twist plugs into each one and called it good. but in reality its not. Kinda makes the whole "Live well" thing almost unusable.

Thanks for any advice,

we replaced all of the thruhulls w/ stainless, however getting to all of the clamps, elbows, and hoses to get good tight connections is impossible. I was just wondering what anyone else may have done that we haven't thought of? This is a real issue for a boat that is in a slip, ultimately we just installed twist plugs into each one and called it good. but in reality its not. Kinda makes the whole "Live well" thing almost unusable.

Thanks for any advice,

DennisG01

GreatGrady Captain

- Joined

- Sep 1, 2013

- Messages

- 7,816

- Reaction score

- 1,542

- Points

- 113

- Location

- Allentown, PA & Friendship, ME

- Model

- Offshore

Unless I'm missing something... you said you already replaced the thru-hulls so you must have been able to get to the clamps to remove them? Which means you should be able to get to them to tighten them - assuming you put the clamp head in the "best" (relative term, there!) position for accessibility. Otherwise, sometimes you need to cut an access hole and cover with a pie plate.I would like to resurrect this thread,

we replaced all of the thruhulls w/ stainless, however getting to all of the clamps, elbows, and hoses to get good tight connections is impossible. I was just wondering what anyone else may have done that we haven't thought of? This is a real issue for a boat that is in a slip, ultimately we just installed twist plugs into each one and called it good. but in reality its not. Kinda makes the whole "Live well" thing almost unusable.

Thanks for any advice,

When you say "all" through hulls are SS. Not the ones below the waterline, I hope? If you trailer, it's not as big of a deal. But since you slip, that's not what you want. SS is not approved for below the waterline since it can corrode. Bronze is, by far, the best.

glacierbaze

Well-Known Member

- Joined

- Jul 6, 2012

- Messages

- 2,566

- Reaction score

- 670

- Points

- 113

- Age

- 76

- Model

- Seafarer

If you can reach the clamp, but the tool is the problem, I like a palm ratchet.

DennisG01

GreatGrady Captain

- Joined

- Sep 1, 2013

- Messages

- 7,816

- Reaction score

- 1,542

- Points

- 113

- Location

- Allentown, PA & Friendship, ME

- Model

- Offshore

And/or get creative with tools... different extensions, etcIf you can reach the clamp, but the tool is the problem, I like a palm ratchet.