- Joined

- Mar 1, 2006

- Messages

- 3,068

- Reaction score

- 1,378

- Points

- 113

- Location

- Berea, KY/Cross, SC

- Model

- Seafarer

Now we let mother nature plug them up for usOP's coffin box could very well be sealed. I saved this from a similar conversation about the tubes being sealed.

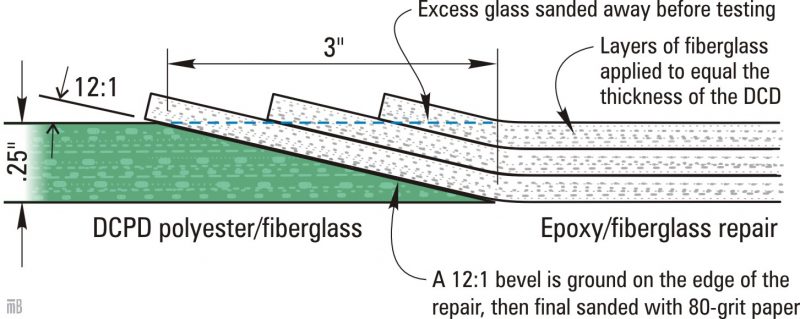

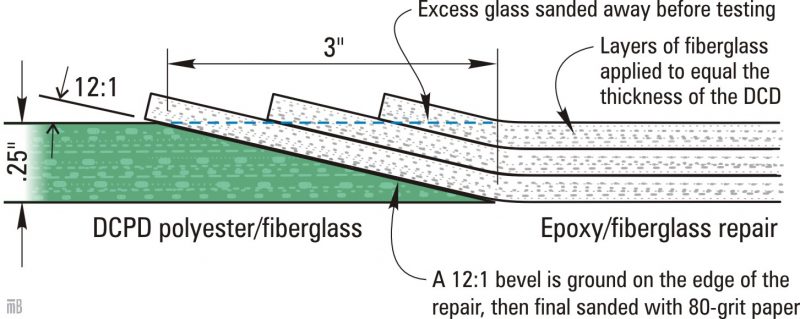

View attachment 28046

Perfect that was one of my questions which was epoxy resin vs poly resin. I'm definitely going to take a look at the tread and get some pointers. Thanks Greauxpete!! I appreciate it.We just finished replacing our starboard stringers on our 268 islander. After sealing all sides of the new plywood stringer with epoxy, we initially glued the new plywood in with peanut butter. Then, we tabbed the new stringer to the floor with 3 layers of 1708. Also, wrapped the top with 3 layers of 1708. We used epoxy due to its increased strength (vs polyester), better adhesion to old polyester, and less fumes. See thread here:

268 Islander stringer repair

Poly is quite a bit less expensive and is plenty strong enough for the job. But I prefer epoxy (and it's what I used, as well), too. Aside from way less stink, it's more forgiving to mix and work with. You're going to go through a lot of it - while I like the West System and it's readily available and they have great "how to's", it is quite a bit more expensive than lesser known brands (I have used it - and will continue to use it at certain times, though). For my big project, I ordered all my stuff from US Composites - including about 5 gallons of epoxy.Perfect that was one of my questions which was epoxy resin vs poly resin. I'm definitely going to take a look at the tread and get some pointers. Thanks Greauxpete!! I appreciate it.

Their pumps are "metered" as you know - which one pump of resin and pump of hardener. Other companies (like the one I mentioned) have pumps, too - but sometimes they're not metered... meaning you control it based on the number of pumps. For example, 3:1 - 3 pumps of resin to 1 pump of hardener.Dennis, I like west systems, among other reasons for the pumps. Can you recommend a comparable lower cost epoxy which has pumps?

I appreciate the post I’m definitely going to be reading into it. I already have the west systems epoxy with the pumps for smaller projects I’ve been doing so I’ll be going this route then. Thanks Dennis for the input I’ll still look into the us composites to see what the savings would look like.West epoxy vs polyester resin:

WEST SYSTEM Epoxy vs. Polyester

Epoxy vs. polyester: Which is the better choice for fiberglass boat repair? Tom Pawlak explores the advantages and disadvantages of each.www.epoxyworks.com

The two 1/2" plys would be stronger. I don't know if there's a significant weight savings one way or the other, though.I appreciate the post I’m definitely going to be reading into it. I already have the west systems epoxy with the pumps for smaller projects I’ve been doing so I’ll be going this route then. Thanks Dennis for the input I’ll still look into the us composites to see what the savings would look like.

I’m now looking into how I’m preparing the wood, I’ve seen some people glass and sand which two half inch boards to make the 1” stringer. Then some people get 1” boards epoxy it with no glass peanut butter it down then glass over it… any preferred methods in trying to stay as light as possible to prepare for a 4 stroke outboard maybe even two small 115s.

Cause I was going to use Douglas fir unless I get any other recommendations, so far I’m leaning with 1” Douglas fir.The two 1/2" plys would be stronger. I don't know if there's a significant weight savings one way or the other, though.

But speaking of strength... I wouldn't pick one of those methods over the other for strength. Strength of the core material actually isn't very important. It's the integrity of the core that matters so it supports the glass.