Re: 1986 Seafarer 227 Repairs, Updates and Upgrades

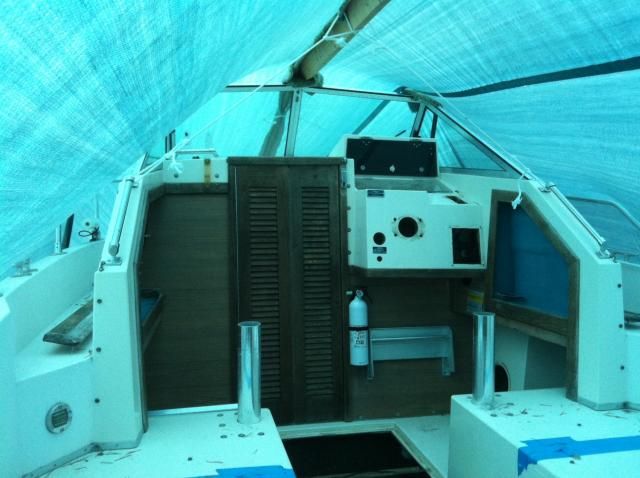

Took advantage of some nice weather yesterday to skip the honey-do list and get a bit of work done on the boat.

I started off by removing the water separator, bilge pump, float switch, bilge hose, excess wiring,etc. Then I removed all the ties securing the boat and old engine harnesses to the transon and set the harnesses aside. Next came scrubbing down the bottom of the bilge to get rid of the oily, dirty mess that was coating everything. I wanted to get that clean so I wasn't tracking it all througout the boat, to reduce the chance of slipping if I stepped in there and so when I start grinding, I'm not contaminating freshly exposed glass with oil, hyraulic fluid, etc.

Once that was all done, I got to cutting on her a little. First to go was the forward engine mount. I was a solid 4x4 block that had to come out in pieces. My reciprocating saw could chew threw the glass and wood, but not through the 1" thick solid putty it was bedded in. So, I would cut down from the top, then do my best to cut the glass against the hull bottom, and hit the section with a sledge hammer to break it free from the putty. As the center pieces came out I saw that there were areas of that mount that had not been sealed and were exposed to bilge water. Surprisingly enough, the mount was not rotten so whatever type of wood was used is natually rot resitant. After the major pieces were out, I chiseled out the remaining scraps and trimmed the glass back a little more. That reaveled there was no barrier between the core of the mount, and the short stringers it ran between.

I wanted to cut out the short stringers entirely, but I chose to leave most of them in for the time being so the hull was still well supported while it's on the trailer. Ended up chopping out the last 9" or so at the transom. These weren't bedded in putty, so they came out easier. Very wet, but not rotten. The good thing is there was glass between the stringer cores and the transom.

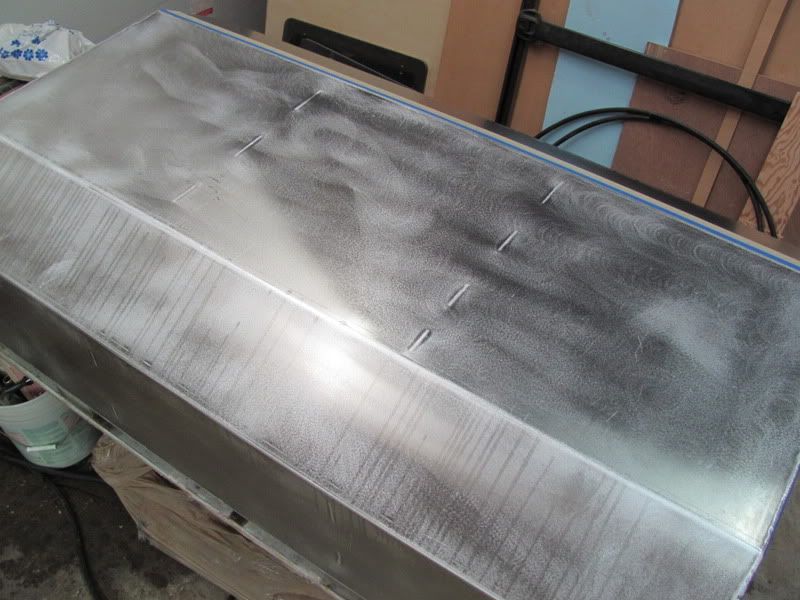

Next step is more clean up. Then I can start trimming back the glass and transom core to prep for filling the outdrive hole.