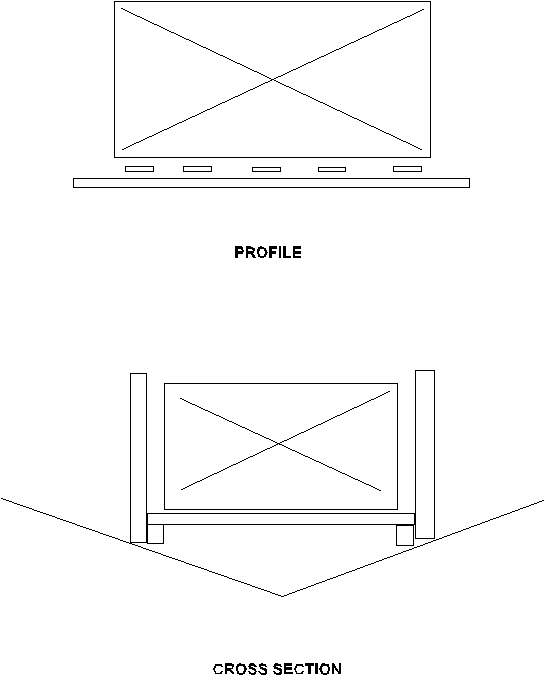

Next is to investigate the amount of water in the fuel compartment and how the drains should be working. The boat has a long 1/2" PVC pipe from the forward bilge to the aft bilge. There are 3 - 1" PVC connectors in each of the bulkheads - forward, center and aft (only aft one shown). I need to confirm there is a forward one.

I expect to find a long pipe connecting the forward bilge to the aft bilge that bypasses (keeps dry) the fuel compartment. That pipe is there but may be freeze damaged. It also appears to be plugged in aft bilge. GW may have decided to isolate forward and aft bilges.

.

There is no plug in the 1" PVC feed thru's (plastic limber holes??). Water can flow from the aft bilge forward. It would also allow a leaking fuel tank to put fuel in the aft bilge.

I would like the forward bilge to dry out and drain back. I'll have to see if that really happens when the boat is in the water. I am going to cap the fuel compartment. I'll be able to see how much water accumulates and contain fuel leaks (hopefully none with new tank).

Question to GW CS:

In the process of replacing fuel tanks. I need to know a few things about how GW handles the bilge under the fuel tanks.

First question is a 1/2" PVC pipe the runs thru the compartment. Does this connect forward and aft bilges and keep water out of the two fuel compartments?

YES

Second question is a.) are fuel compartments separated (do they drain into each other?

YES ) b.) do the fuel compartments drain into the aft bilge?

YES unless plugged.

SP Sheet Metal said leave all the openings open. Let the water out of the compartment. The tank killer is water against the tank sandwiched between other material. Nitrile strips should be attached to the tank with 3M 4000 or 5200. When dry do all the edges. Nothing in contact with the tank that isn't 4000 or 5200'ed down - no voids. Look at both of the old tanks. The glue on the neoprene strips failed but stayed in place. You can see the corrosion line where the strip trapped water.

Investigated the drain hoses today. The long tube does connect the forward bilge with the aft bilge. This pipe runs thru the fuel compartment. GW plugged it though in the aft bilge. The forward end was open and crap got into the pipe. Had to cut the pipe and snake it out.

The forward fuel compartment connects to the aft fuel compartment and that connects to the aft bilge. All thru 1" pipe couplings. This was not plugged although it could be to contain a leaking tank.

EDIT 8/26/23: the 1/2" PVC connects the forward and aft bilges. The 1" PVC is a short feed-thru connecting forward and aft tank compartments and another one connecting the aft fuel compartment and aft bilge. If you have the forward tank out snake out the 1/2" PVC and make sure forward bilge is squeaky clean and free of debris. Same with fuel compartments. Also make sure 1/2" PVC is intact and not freeze damaged. Fill forward bilge and observe fuel compartments - should be no water. You can decide if you want to plug the forward bilge PVC (mine was) or the fuel compartment to aft bilge (mine wasn't).