- Joined

- Apr 13, 2019

- Messages

- 329

- Reaction score

- 117

- Points

- 43

- Age

- 58

- Location

- San Francisco Bay Area

- Model

- Seafarer

After going back and forth on the future of fuel holding and boat balance for the 226, a decision has been reached. Gave serious thought to replacing the main and only tank currently rigged. The idea was have a new 92 gallon tank built and move the location forward to balance out the added weight of the new F250 and the T9.9 kicker. Placement of the fill, vent and sender repositioned to remain under the deck inspection plates. This was drawn out and quotes received from a number of fabricators from local to Florida. Prices shipped to my business was from $875 to $2100.

Since the main tank has yet to reveal any leaks and after inspection of tank it appears sound (knowing this “appearance” can be very deceiving), I began to rethink things. Knowing that Grady was kind enough to rig for an aux tank even if not installed and the hoses looked like new, I thought maybe add the second tank. Received drawing from GW. Back to sourcing fabricators. Found a local commercial aluminum boat builder who was looking for small projects between builds and I gave him the job. He turned out to be a very poor communicator and after not hearing from him for a couple weeks, went back to my original plan of the relocated main tank. Ordered up from a shop in Arizona for a really great price (but 1 month lead-time). Two days later, local guy says your tank is ready, WTF? Ok, contacted shop in Arizona and provided a redesign with original GW 92 gallon tank. No issue with them as they had not started tank.

So, I will have factory spec’ed main and aux tank when done. Found correct switch, McGill 0852-269, SPDT to swap between senders. Side note, GW even has pink/white sender wire rigged for aux tank. At switch panel they routed the main tank sender wire the full length of the switch panel and back to gauge to allow for cutting and terminating at switch (pink wire). Well thought out. New Perko fuel fill, Moeller Fuel Tank Three-Way Valve with fittings, various SS hose clamps and 25’ of 3/8” fuel line.

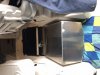

Picked up new aux tank last night. Work appears good. Plan on using 1/2” thick, 2” strips of neoprene glued to tank for mounting. Need to lift coffin lid later and dry fit to get a better idea for final fitting. Started rigging today. Fill/vent installed and hoses fastened. Kind of a pita. Tight quarters and no leverage. Switch wired and valve installed.

Few pics of progress and will update as progress continues:

Since the main tank has yet to reveal any leaks and after inspection of tank it appears sound (knowing this “appearance” can be very deceiving), I began to rethink things. Knowing that Grady was kind enough to rig for an aux tank even if not installed and the hoses looked like new, I thought maybe add the second tank. Received drawing from GW. Back to sourcing fabricators. Found a local commercial aluminum boat builder who was looking for small projects between builds and I gave him the job. He turned out to be a very poor communicator and after not hearing from him for a couple weeks, went back to my original plan of the relocated main tank. Ordered up from a shop in Arizona for a really great price (but 1 month lead-time). Two days later, local guy says your tank is ready, WTF? Ok, contacted shop in Arizona and provided a redesign with original GW 92 gallon tank. No issue with them as they had not started tank.

So, I will have factory spec’ed main and aux tank when done. Found correct switch, McGill 0852-269, SPDT to swap between senders. Side note, GW even has pink/white sender wire rigged for aux tank. At switch panel they routed the main tank sender wire the full length of the switch panel and back to gauge to allow for cutting and terminating at switch (pink wire). Well thought out. New Perko fuel fill, Moeller Fuel Tank Three-Way Valve with fittings, various SS hose clamps and 25’ of 3/8” fuel line.

Picked up new aux tank last night. Work appears good. Plan on using 1/2” thick, 2” strips of neoprene glued to tank for mounting. Need to lift coffin lid later and dry fit to get a better idea for final fitting. Started rigging today. Fill/vent installed and hoses fastened. Kind of a pita. Tight quarters and no leverage. Switch wired and valve installed.

Few pics of progress and will update as progress continues:

Last edited: