- Joined

- Sep 11, 2023

- Messages

- 70

- Reaction score

- 42

- Points

- 18

- Age

- 41

- Model

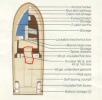

- Offshore

After almost 4 decades it's a moot point, now. Things could have been changed many times. If you're curious if you have a second tank or a fresh water tank - you'll need to pull hatches to check.

EDIT: Was there something more to this? Or an underlying reason you wanted to know?

I was just reading another thread about a guy with an offshore and he was commenting about his aux tank. I've read different information on various websites about this model, some stating it had 2 tanks, other saying it had 93 (or 96, can't remember) gallon fuel capacity. I guess to answer your question, I just want to know what I have under my feet. I'll be able to answer my own question soon enough since I need to recore the hatch anyway over the winter. Is the fill for the fresh water tank on the starboard side near the fuel fill? That's the location of the fill that was glassed over on my boat.